What is a rough timing estimate for the entire job?.What type of resources are needed? How much of each?.How many hours would take to do each task?.How much of what raw material would you need?.Here are the questions that should be considered in the production planning stage: The Planning Process Answers the HOW and WHAT questions. In manufacturing planning and scheduling software, a comprehensive routing feature can give you clear visibility on how a customer order needs to be completed. In Summary, the routing screen is an accurate roadmap of the production. These could be the required equipment, number of labor, skills required, parts, raw materials, tools, or other specific considerations.

#Manufacturing production software software

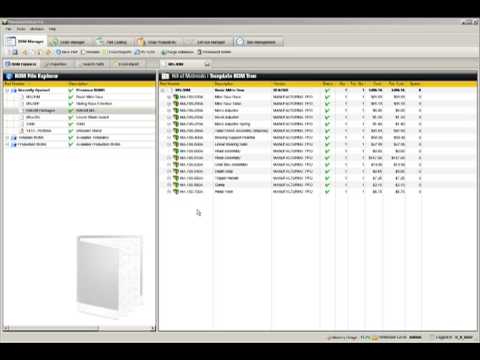

One important outcome of this stage is defining the sequence of tasks to finish a customer order/work order/manufacturing order.įurthermore, in production scheduling software for manufacturing, the routing screen contains other information for each step. The manufacturing routing process outlines the required tasks to produce a product or finish a production process. Similarly, the planning stage prepares the forecasting reports to estimate the overall cost of the order and its completion time. The planning process lays out the required material. It is about breaking down the production process into tasks and sequencing them in order. Production planning is about creating an accurate plan to carry out production.

#Manufacturing production software how to

In this guide, we look at a few key features in production scheduling software for manufacturing. We put together this guide to help you gain some of that knowledge. There is some learning curve in the process that you need to master. Since the manufacturing planning and scheduling software with the most bells and whistles might not be a good match for your type of operation. Second, you need to assess which ones are beneficial to your manufacturing operation. First, you want to learn about the existing features, and what they can do. How do you start finding the right production scheduling software for your manufacturing operation? The right solution is about finding a suitable match between your operation’s needs and the features of the scheduling software.

What is the right production scheduling software for your operation? When it comes to manufacturing planning and scheduling software, having the right product is the key to its successful implementation.įinding the right manufacturing planning and scheduling software allows manufacturers to save time, reduce costs and stay ahead of the competition in their field. Therefore, they benefit the most from flexible planning and scheduling software. This also means that they face more challenges in production planning and scheduling. As a result, they spend more time in the planning stage of production. This guide looks at the place of production scheduling software in make-to-order manufacturing, job shops, and service industries.īecause in contrast to assembly line factories, these businesses have more variety in their incoming customer orders. Further, it enables businesses to control their labor and equipment costs and lower their overheads. The right production scheduling software for manufacturing increases throughput and efficiency. Production scheduling software enables manufacturing businesses to optimize their processes. Home QShop Software » Production Scheduling Software for Manufacturing

0 kommentar(er)

0 kommentar(er)